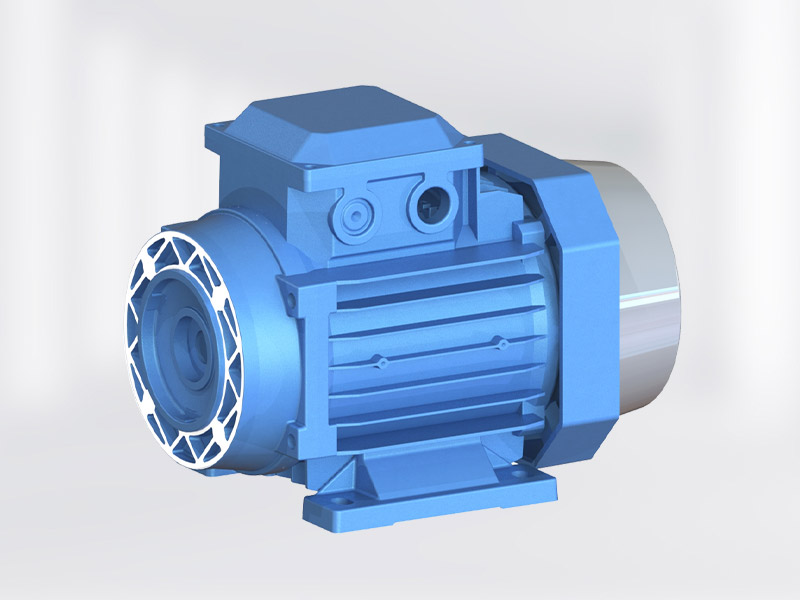

PRODUCT LIST

- YE3 aluminum alloy die-casting motor housing series

- Y2- square aluminum alloy die-casting motor housing series

- Y2- tristyle aluminum alloy die-casting motor housing series

- Y2- four-style aluminum alloy die-casting motor housing series

- Y2- Grundfos aluminum alloy die-casting motor housing series

- IEC aluminum alloy die-casting motor housing series

- AO2 aluminum alloy die-casting motor housing series

- YS aluminum alloy die-casting motor housing series

- JW aluminum alloy die-casting motor housing series

- Cleaning machine, negative pressure blower, RHEKEN pump.

Factors that affect the surface roughness of the motor housing

Machining and manufacturing industry, especially each workpiece processed by the motor shell has its surface roughness requirements, and its quality directly affects the appearance and performance of the use.

1. The selection of tools, the different materials of the workpiece, the selection of tools is different, otherwise the processing performance of the tool is not perfectly reflected, and even does not have machinability.

2. In order to ensure a good surface roughness, the feed speed of fine knives is usually very slow.

3. The selection of speed, in order to achieve the requirements of better surface roughness, the speed of the motor shell is usually higher, so that the inner wall of the motor shell will be brighter and brighter, and the roughness will be better.

4. The selection of machine tools and equipment, the selection of automatic processing precision of CNC equipment.

5. Cast iron motor shell, casting stability of the surface to be machined, whether the machinability is good, etc. Of course, in the process of processing the motor shell, there are many factors that affect its surface roughness, which still need to be overcome and solved.

Mobile station

Mobile station Add friends to inquire now

Add friends to inquire now